ZuZu

Well-Known Member

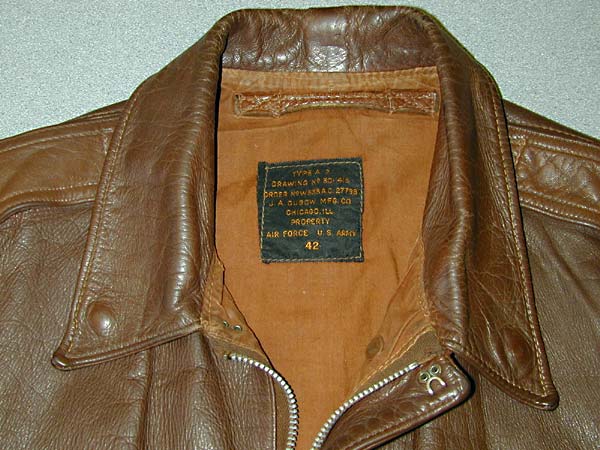

So I was looking at the "What's new" section and I saw that someone posted a pic of a Buzz Rickson Dubow. It is a beautiful jacket but it has an incorrect detail I thought I'd point out. On original non-collar-stand Dubows the zipper tape is sewn all the way up the inside of the windflap and actually dives into the intersection of collar/windflap/neckhole. Here are a few examples:

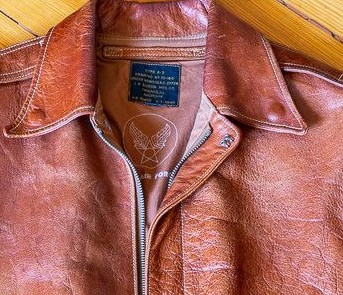

On the Buzz Rickson Dubow the zipper tape is actually folded over before it reaches the top of the windflap- like an Aero and other contracts:

On the Buzz Rickson Dubow the zipper tape is actually folded over before it reaches the top of the windflap- like an Aero and other contracts: